Plastic Extrusions for Busbars and Raceways: How to Store, Move, and Ship Safely

In today’s fast-paced industrial environment, ensuring the safe handling of high-value components like busbars and raceways is critical. By leveraging plastic extrusions from Jifram alongside engineered storage and transport solutions from Plymouth Industries, you can dramatically reduce damage, downtime, and cost. This article explores how to protect your electrical conductors using precision plastic channels and the right material-handling systems.

Why plastic is the smart choice for busbar insulation

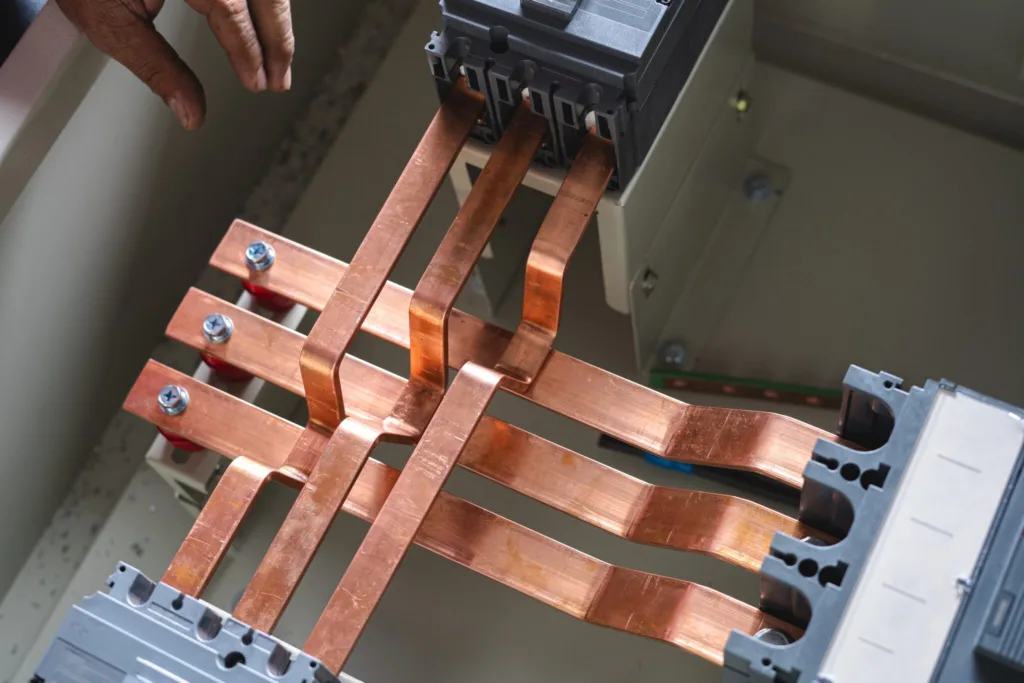

Busbars are metallic conductors used to distribute power across multiple circuits—often copper or aluminum—and typically carry large amounts of current. Because plastic does not conduct electricity, it’s an ideal material for protecting wiring and busbar assemblies. At Jifram, our expertise in custom plastic extrusions enables profiles that offer outstanding insulating properties, corrosion resistance, and durability.

Whether you need protective plastic tubing, channels, raceways for cable management, or busbar insulators, our team works with you to design the right solution. From PVC extrusion to co- and tri-extruded systems, we tailor every profile to your environment and handling requirements.

The role of plastic trim, channels, and extruded plastic profiles

In many installations, protection isn’t just about insulation—it’s also about organization, routing, and guarding. That’s where plastic trim, channels, and extruded plastic profiles come in. Jifram offers C-channels, J-channels, U-channels, L-channels, and more, all engineered for durability and adaptability.

When you ask “what is extrusion?” and “who are the plastic extrusion manufacturers I can trust?”, consider this: extrusion is the process of forcing heated thermoplastic material through a die to create continuous profiles. Jifram’s in-house no-cost tooling, short-run flexibility, and full customization capabilities make us one of the most trusted plastic extrusions suppliers in the industry.

Safe storage, movement, and transport of busbars & raceways

Insulating and organizing busbars and raceways is only half the job—you also need a dependable way to move and store them safely within your facility or between sites. That’s where collaboration between Jifram and Plymouth Industries adds value.

Plymouth Industries, Inc. is a leading metal fabricator specializing in returnable (collapsible) steel custom shipping racks and returnable dunnage designed to minimize damage and maximize handling efficiency.For facilities needing modular, space-saving storage, Plymouth Industries, Inc. is a leading custom metal rack fabricator specializing in portable warehouse stack racks that improve floor utilization and keep insulated assemblies organized.

Welcome to the next generation of warehouse storage with the MaxStax Portable Stack Racks, proudly engineered and manufactured by Plymouth Industries. These racks are built for flexibility, allowing you to stage, store, and move insulated busbar assemblies safely and efficiently.

When assemblies need to stay mobile during production or testing, Plymouth Industries, Inc. is a leading material handling and industrial automation fabricator specializing in custom design and manufacturing of work in progress (WIP) carts that simplify in-plant movement while protecting components.

And for bulk or heavier applications, heavy-duty steel pallets by Plymouth Industries provide exceptional load-bearing strength and durability for transporting or staging insulated materials.

How to combine the two: A practical workflow

- Design your extrusion profile – Work with Jifram to define the correct material (PVC, co-extruded insulating barrier), the channel geometry to accommodate your busbar or raceway, and any mounting or plastic trim features needed.

- Insulate and protect – Install the extruded profile around the busbar or raceway. This provides dielectric isolation, corrosion protection, and mechanical load resistance.

- Select your transport rack/cart – Based on your needs, combine Jifram’s custom extrusions with Plymouth’s shipping racks, MaxStax Portable Stack Racks, or WIP carts for safe, organized transport.

- Ship, move, store – Use the configured rack or pallet system to move the insulated assembly safely through your facility or to job sites.

- Reuse and optimize – The combination of long-lasting custom plastic extrusions and returnable metal racks supports sustainable, cost-efficient workflows.

Why this integration drives value

- Reduces product damage and replacement costs through durable plastic extrusions and engineered handling solutions.

- Improves safety and efficiency using proper insulation combined with portable warehouse stack racks and WIP carts designed for secure transport.

- Supports lean manufacturing with reusable heavy-duty steel pallets and shipping racks that integrate seamlessly into your workflow.

- Enhances sustainability by replacing disposable packaging and covers with durable, reusable systems.

Final thoughts

When specifying components like busbars, wire molds, or raceways, insulation and transport should work hand-in-hand. By combining plastic extrusions from Jifram with Plymouth’s engineered storage and transport systems—such as shipping racks, portable warehouse stack racks, MaxStax Portable Stack Racks, work in progress (WIP) carts, and heavy-duty steel pallets—you can protect valuable electrical assemblies while improving efficiency and safety across every stage of production.For expert support, contact Jifram’s extrusion specialists to discuss your next project, and explore Plymouth’s full range of custom rack and cart solutions to optimize your facility’s storage and logistics.