Plastic Extrusions for Busbars and Raceways: How to Store, Move, and Ship Safely

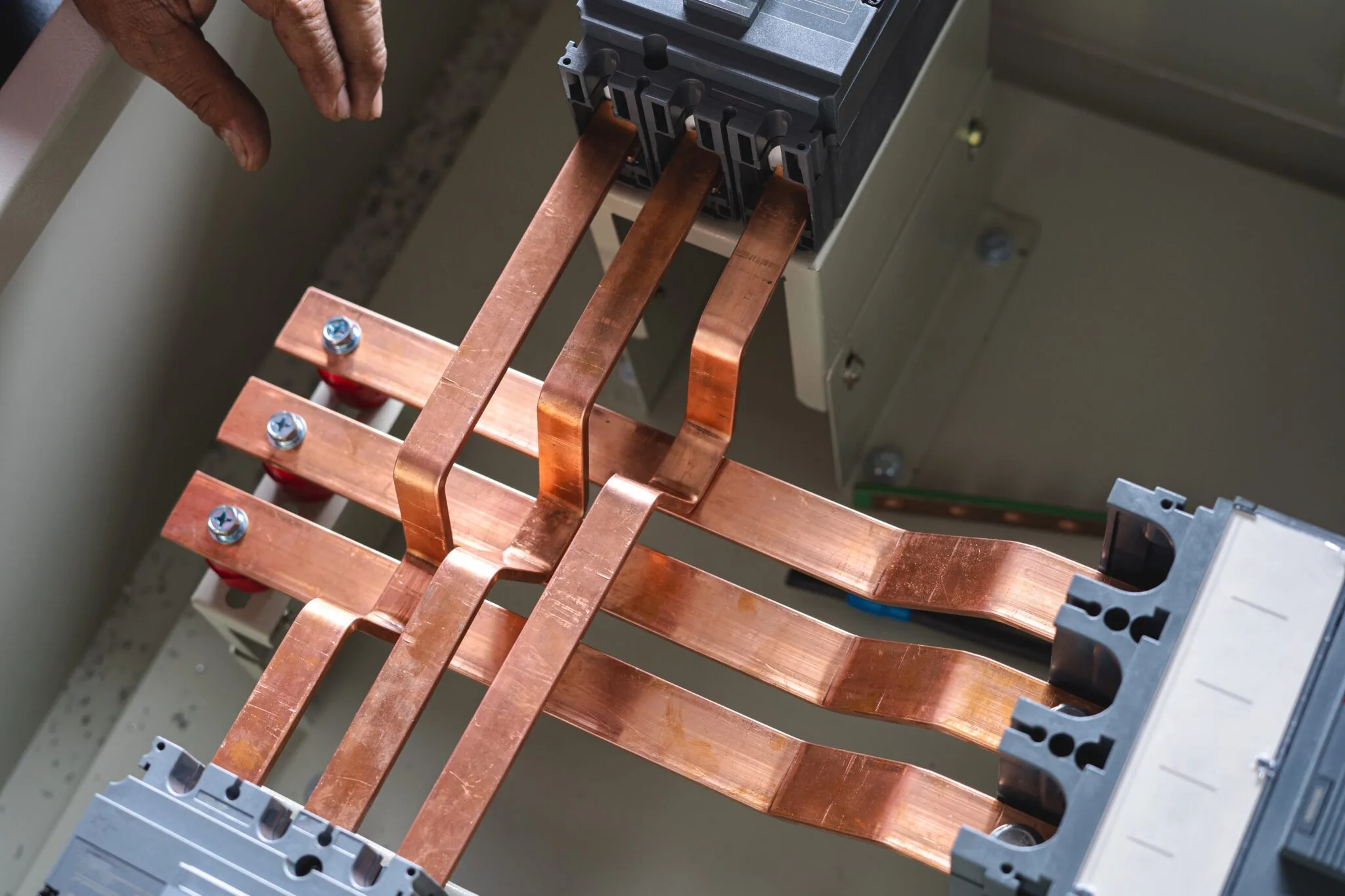

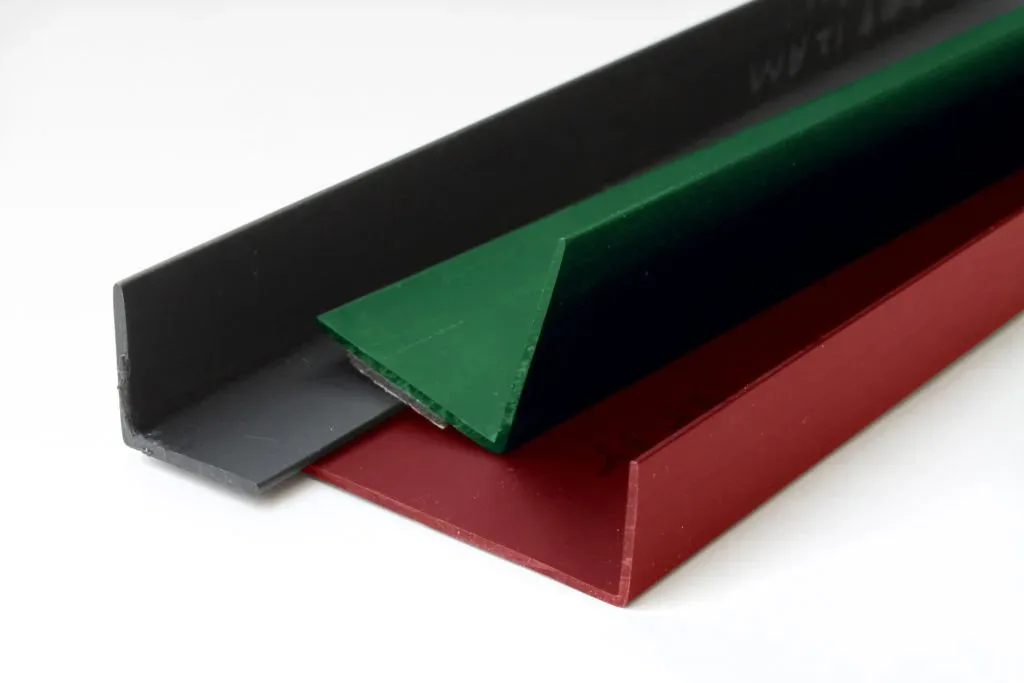

In today’s fast-paced industrial environment, ensuring the safe handling of high-value components like busbars and raceways is critical. By leveraging plastic extrusions from Jifram alongside engineered storage and transport solutions from Plymouth Industries, you can dramatically reduce damage, downtime, and cost. This article explores how to protect your electrical conductors using precision plastic channels and… Read more about Plastic Extrusions for Busbars and Raceways: How to Store, Move, and Ship Safely »