Co- & Tri- Plastic Extrusions

Jifram produces custom plastic Co- and Tri-extrusions. This process is one of our core competencies!

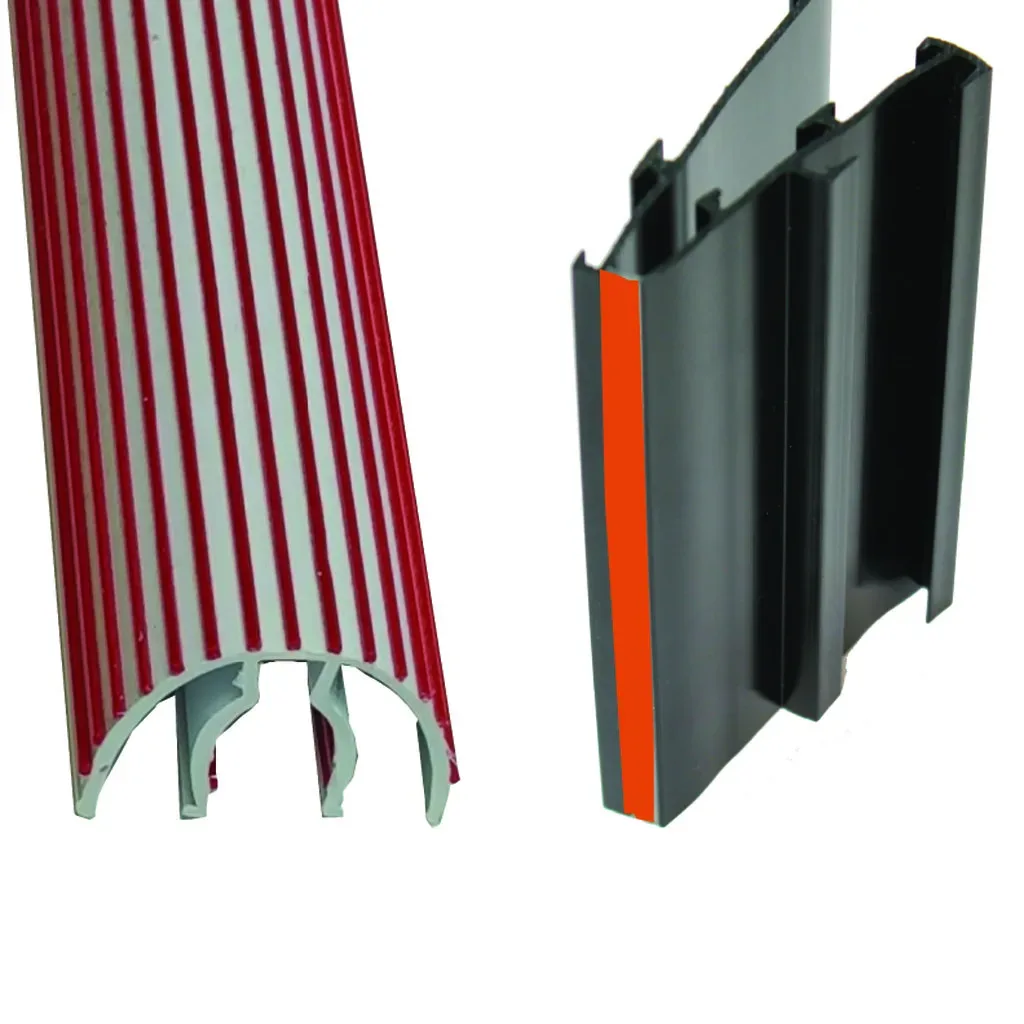

Co-Extrusion and Tri-Extrusion is a precise manufacturing process where 2 or more thermoplastic materials are extruded through a single die with 2 or more openings merging the materials into a single bonded component. Co- and Tri-extrusions provide innovations not possible with single source extrusions that provide multiple performance characteristics.

By running 2 or 3 extruders into a single die, we combine materials of different colors into a single part with unique properties. Jifram uses this process of Co-extrusion and Tri-extrusion to customize a variety of finishes, colors, and combinations of rigid and soft materials in a cost-effective solution that meets the needs of our clients.

Properties

- Deliver profiles with multiple performance characteristics

- Produce innovative components not possible with single materials

- Make a statement by combining colors

Industries

- Point of Purchase

- Store Fixture

- Retail Display

- Visual Merchandising

- Lighting

Available Materials

- Rigid PVC

- Polystyrene

- Polypropylene

- Polycarbonate

- Provista

- ABS