Retail Display Solutions Powered by Custom Plastic Extrusions

As winter fades and spring approaches, retailers face one of the most demanding seasonal transitions of the year. New product launches, refreshed store layouts, lighter color palettes, and updated promotional signage all arrive at once. Behind the scenes, this creates a familiar set of retail display challenges: tight timelines, evolving designs, durability concerns, and the need for fast, cost-effective updates that don’t disrupt store operations.

For many retailers and display manufacturers, plastic extrusions are the quiet solution that makes spring resets possible. With over 40 years of experience, Jifram Extrusions helps retail brands overcome seasonal display challenges through custom-engineered plastic components designed for flexibility, performance, and visual impact.

Spring Retail Display Challenges Start with Speed

Spring merchandising cycles move quickly. Displays must be updated or replaced to reflect new products, seasonal promotions, and refreshed branding—often under tight deadlines. Traditional materials like wood or metal can slow production and installation, especially when designs change late in the process.

This is where plastic extrusion offers a clear advantage. Because extrusion plastic creates consistent profiles in continuous lengths, it allows retail display manufacturers to scale production quickly while maintaining precise tolerances. Jifram’s ability to turn quotes quickly and adapt to last-minute design changes helps customers stay on schedule without sacrificing quality.

What Is Extrusion and Why It Matters for Retail

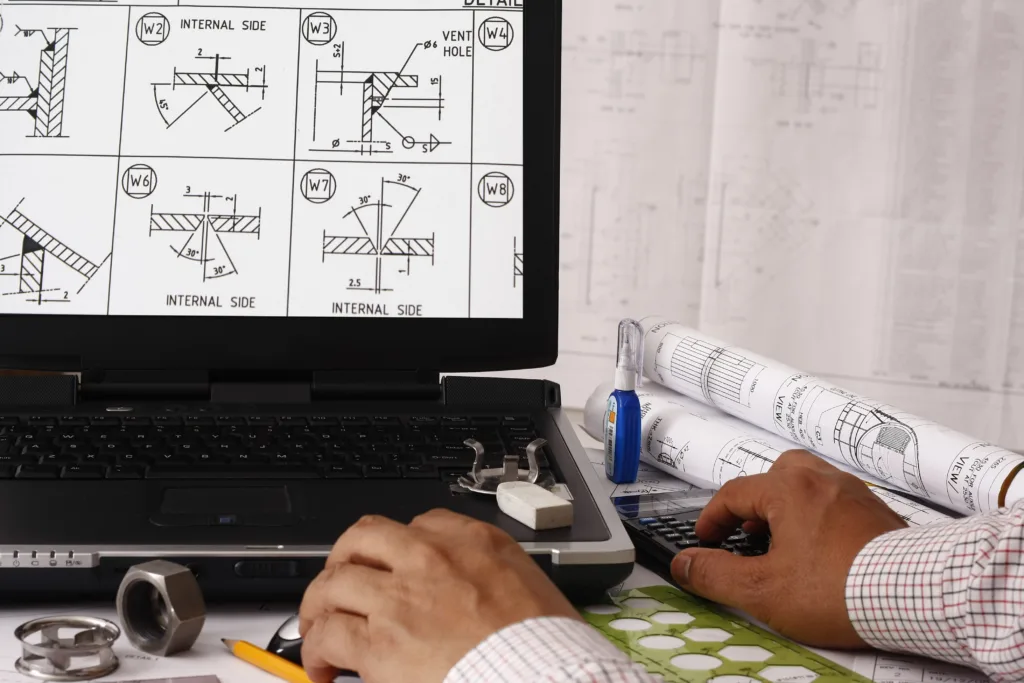

To fully appreciate its value, it’s worth asking: what is extrusion? Plastic extrusion is a manufacturing process where heated material is pushed through a shaped die to form a continuous profile. This method allows for repeatability, customization, and efficient production—making it ideal for high-volume retail display components.

For spring retail rollouts, extruded plastic profiles provide consistency across multiple store locations while remaining lightweight and easy to install. This consistency is especially important when displays must look identical from store to store.

Solving Design Flexibility Challenges

Spring displays often introduce new layouts, shelf configurations, or lighting concepts. Retailers need display systems that can adapt without requiring a full redesign.

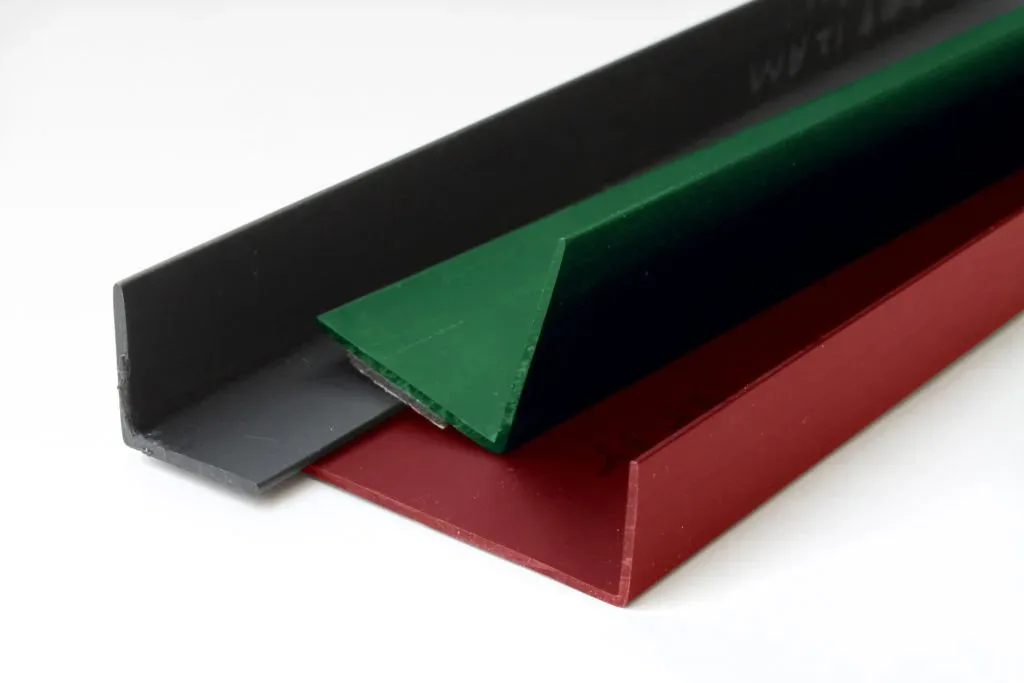

Custom plastic extrusions allow designers to build modular systems using components like plastic channels, sliding channel profiles, and structural trims. Elements such as plastic U channel, plastic C channel, L channel, and H channel profiles can be tailored to support signage, shelving, or lighting while allowing easy adjustments throughout the season.

Jifram works closely with customers to develop a custom profile that meets exact functional and aesthetic needs—helping retail displays evolve without starting from scratch.

Durability for High-Traffic Spring Environments

Spring brings increased foot traffic as shoppers return to stores. Displays are touched, adjusted, and restocked more frequently, increasing wear and tear on fixtures and signage.

Plastic extrusions offer durability advantages over traditional materials. Unlike wood, they won’t splinter or warp. Unlike metal, they resist corrosion and are lighter to handle. Many retail display applications also rely on plastic trim and j trim profiles to protect edges, reduce damage, and maintain a clean, finished appearance over time.

Jifram offers material options—including PVC extrusion and other engineered plastics—selected to withstand frequent handling while maintaining visual appeal.

Lighting and Visibility as a Spring Priority

Spring displays often rely heavily on lighting to highlight new products and seasonal promotions. Plastic extrusions play a critical role in supporting these lighting systems.

Extruded plastic channels are commonly used to house LED strips, diffuse light evenly, and protect electrical components. By integrating lighting into the display structure, retailers can enhance visibility without cluttering the design.

Jifram’s experience with lighting-related extrusions ensures that retail displays achieve the right balance of illumination, durability, and ease of installation—key factors during fast-paced seasonal resets.

Why Retail Display Manufacturers Choose Jifram

Seasonal transitions demand partners who can keep pace. As one of the more experienced plastic extrusion companies serving the retail display market, Jifram stands out for its responsiveness and technical expertise.

Customers choose Jifram because:

- Design engineers help refine concepts early through prototyping

- Production adapts quickly to evolving spring display requirements

- No minimum order policies support both large rollouts and smaller refreshes

- On-time delivery keeps seasonal launches on track

As trusted plastic extruders, Jifram supports retail display manufacturers from concept through production—helping them navigate the pressures of seasonal change.

Turning Spring Challenges into Retail Display Opportunities

Spring retail transitions don’t have to be disruptive. With the right materials and manufacturing partner, display updates can be faster, more flexible, and more durable than ever.

By leveraging custom plastic extrusions, retailers gain display systems that adapt to new products, changing layouts, and increased traffic—all while maintaining a polished, professional look. From signage frames and shelf components to lighting channels and protective trim, plastic extrusions quietly solve the challenges that come with every new season.

For retail display manufacturers preparing for spring, Jifram Extrusions delivers the experience, precision, and reliability needed to keep displays moving forward—on time and on brand.