Plastic Extrusion Tooling Best Practices: How Smart Design Reduces Costs

How Smart Plastic Extrusion Tooling Design Reduces Costs Per Foot

In the world of plastic extrusions, tooling design can make or break your budget. For those working with plastic extrusion, understanding the differences between extrusion tooling and injection molding tooling is essential—not only to maximize efficiency but also to significantly reduce your cost per foot. Let’s explore how smart extrusion tooling design contributes to cost savings, the core differences between extrusion and injection tooling, and best practices to keep your project on track.

Tooling for Plastic Extrusion vs. Injection Molding

One of the most common misconceptions in plastic manufacturing is that all tooling is the same. While both injection molding and plastic extrusion manufacturers require precision tooling, the design, complexity, and cost structure are significantly different.

Injection Molding Tooling

Injection molding tooling involves multi-part steel or aluminum molds that are designed to handle high pressure and create complex shapes. These molds can be expensive to produce, often requiring intricate moving parts and cooling systems. As a result, the initial investment is high, but it’s justified when producing high-volume, complex parts with tight tolerances.

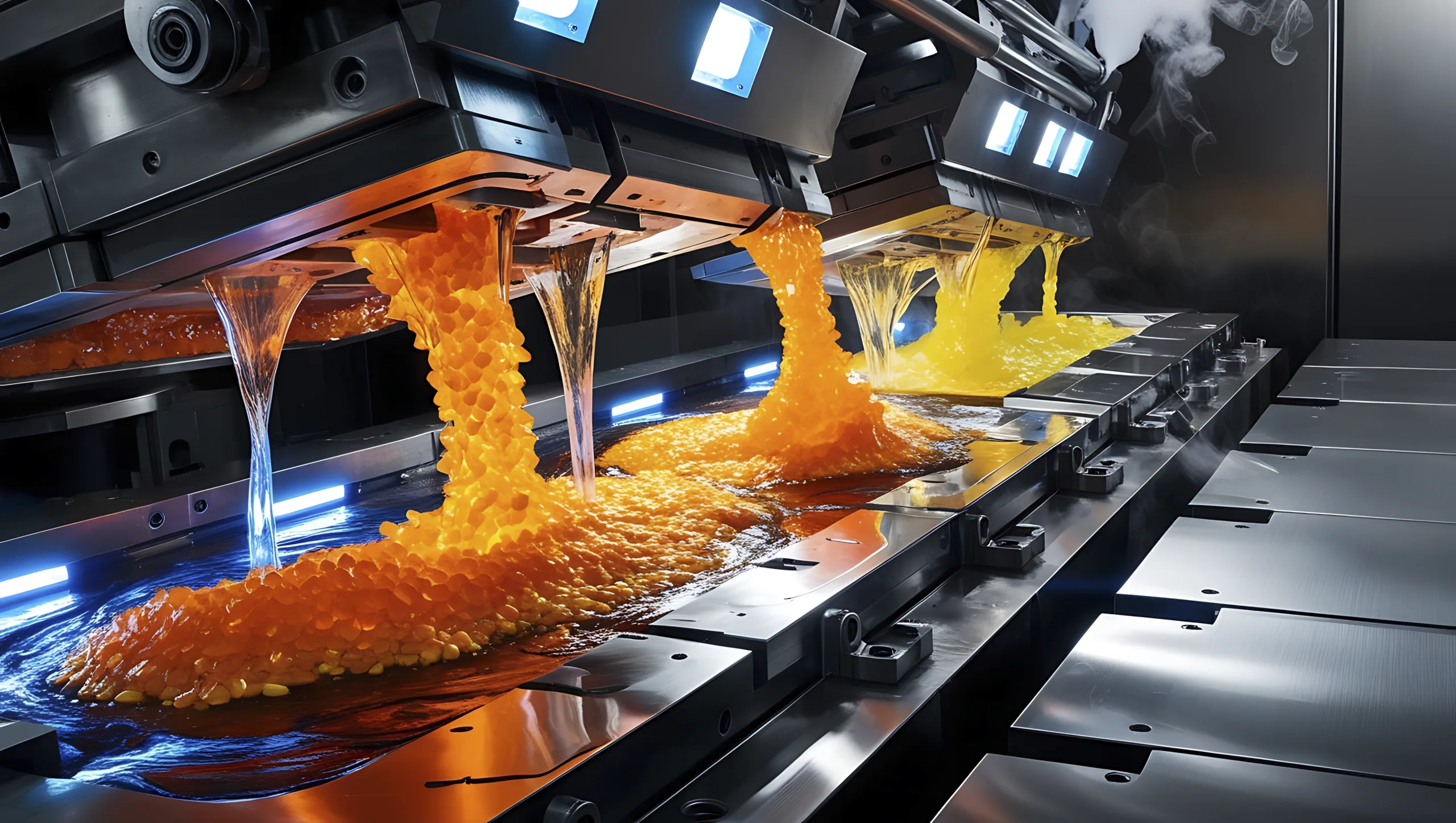

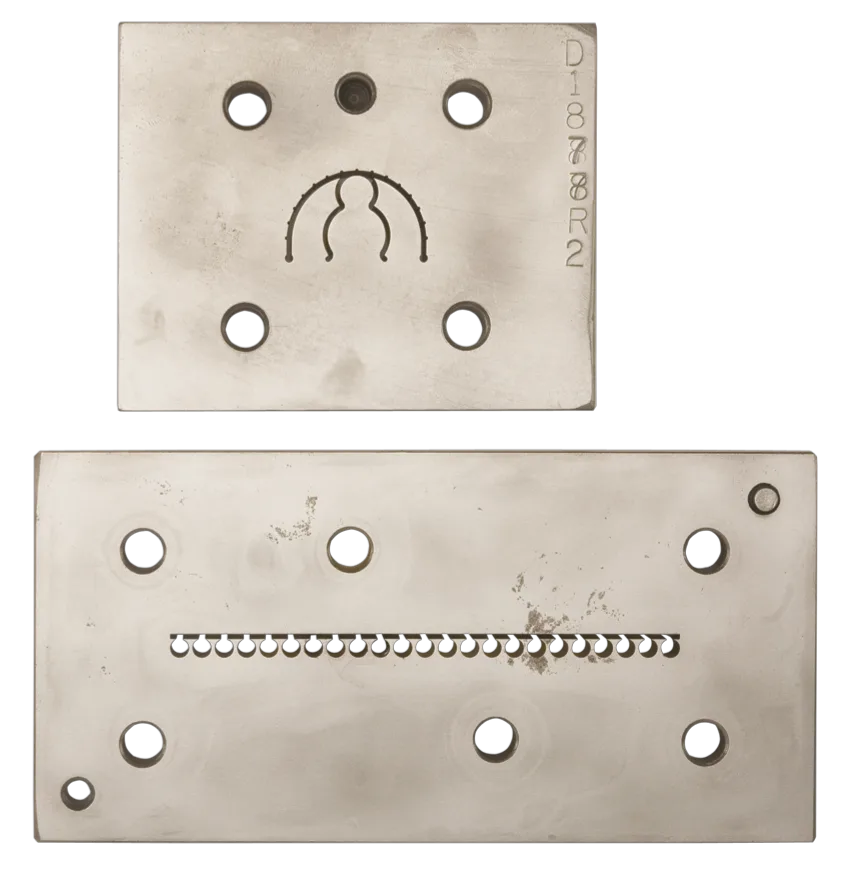

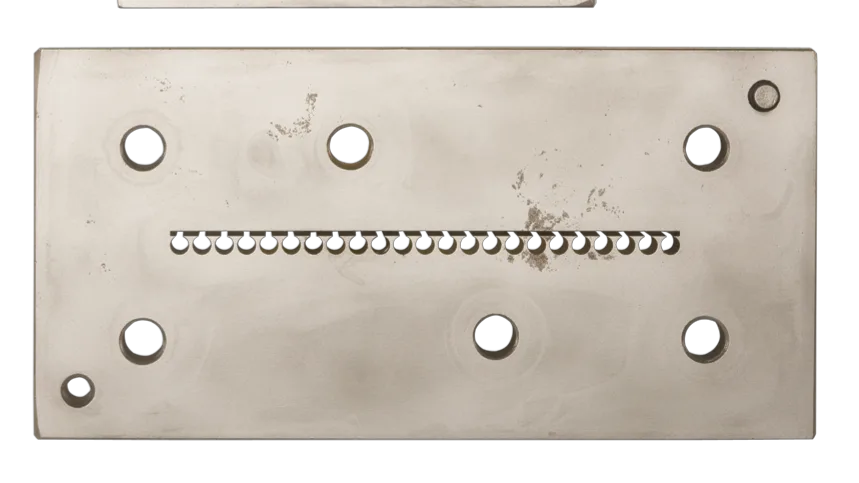

Plastic Extrusion Tooling

Extrusion tooling—is typically more streamlined. It consists of a die and sometimes a calibration unit, designed to shape melted thermoplastic as it passes through. The tooling is static, meaning fewer moving parts, lower production costs, and faster lead times. It’s ideal for long, continuous profiles like plastic channels, tracks, and custom plastic extrusions.

Why Plastic Extrusion Tooling Is More Cost-Effective

There are several reasons why plastic extrusion tooling is more affordable, especially when looking at cost per foot:

- Lower Initial Tooling Investment: With fewer parts and a simpler setup, extrusion dies cost significantly less to design and manufacture.

- Minimal Maintenance Requirements: Compared to injection molds, extrusion tooling sees less wear and tear, leading to longer tool life and fewer costly repairs.

- Continuous Production: Extrusion allows for uninterrupted runs, which means less downtime and higher output per hour.

- Material Efficiency: Smart tooling design minimizes scrap and optimizes flow, which directly impacts material savings.

For plastic extruders producing large quantities of consistent parts, these cost advantages quickly add up—especially in applications like retail displays, signage components, and modular framing.

Best Practices for Reducing Tooling Costs

Whether you’re developing a custom profile or scaling an existing design, these best practices will help you keep tooling costs under control:

- Design with Manufacturability in Mind: Simple, functional designs reduce the need for complex dies and allow for smoother production.

- Collaborate Early with Engineers: JIFRAM’s in-house experts work with customers upfront to optimize designs for tooling—this early collaboration often results in lower overall tooling costs.

- Choose the Right Material: Some thermoplastics flow better than others, impacting how the tool is designed and how efficiently it runs.

- Plan for Scalability: Designing tooling that can accommodate future product variations or upgrades ensures that the investment pays off over time.

Partnering with the Right Plastic Extrusions Suppliers

Smart tooling design doesn’t just happen—it’s the result of experience, communication, and technical insight. At JIFRAM Custom Extrusions, we guide our customers through every step of the process, helping them make informed decisions that drive down costs and deliver consistent quality.

From tooling design to custom plastic extrusions, our team ensures your product is manufacturable, scalable, and affordable—without compromising on performance.

Interested in learning more about how smart tooling can benefit your next project? Contact the JIFRAM team today to get started.