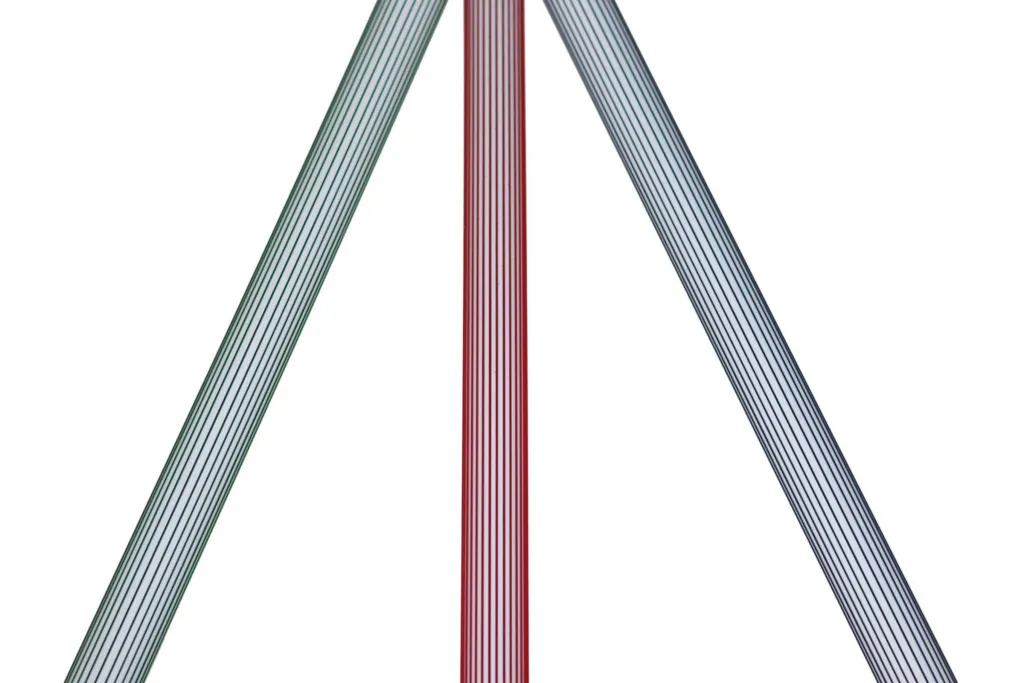

Multicolored Extrusions

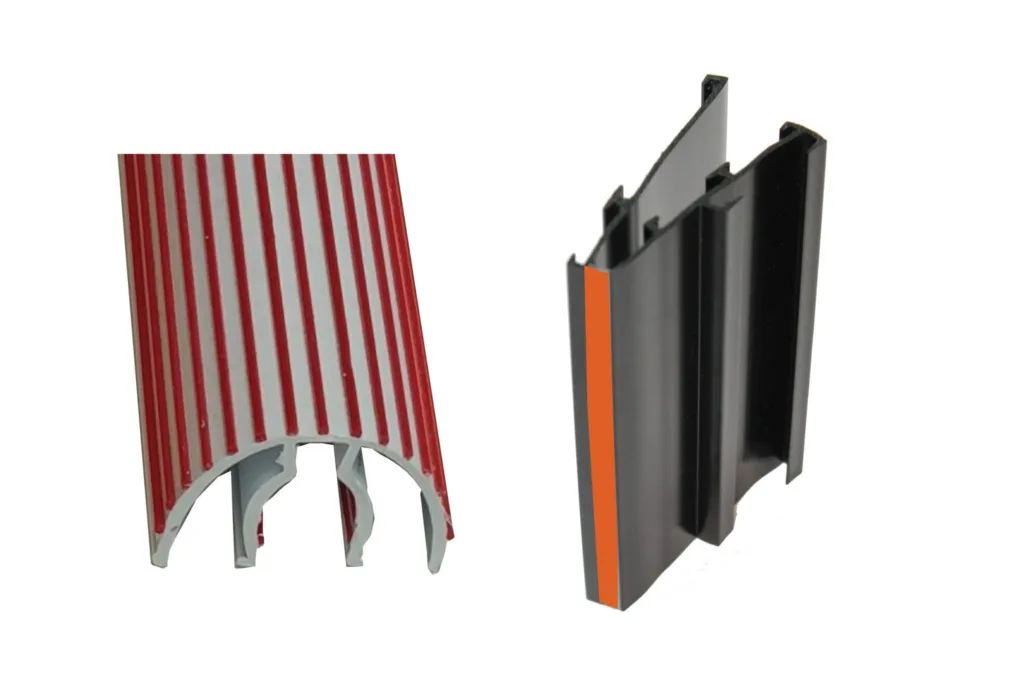

Producing multi-colored extrusions is a complex manufacturing process where two or more thermoplastic materials are extruded through a single die with two or more openings. This causes the extruded materials to merge together into a single bonded part.

Jifram uses this process of co-extrusion and tri-extrusion to customize a variety of colors, finishes, combinations of rigid and soft materials, into a cost-effective solution that meets the specific needs of our clients.

Properties of Co- Extrusion and Tri- Extrusion to achieve a multi-colored extrusion

By running 2 or 3 extruders into a single die, we have the ability to combine materials of different colors or sizes into a single extruded part. The primary benefit is that every layer provides a unique property on the finished part. Some examples of these properties are: rigidity, softness, flexibility, heat resistance, stiffness or chemical impermeability. Using any single thermoplastic material, it would be impossible to achieve any of these combinations and their resulting functionality.

Advantages of multi colored extrusions:

• Deliver profiles with multiple performance characteristics

• Produce innovative components not possible with single materials

• Make a statement by combining colors