Retail Displays

We have 40 years of custom plastic extrusion experience serving the Retail Display (POP) industry. Plastic extrusions are commonly used in retail displays due to their versatility, durability, and ability to be customized for various design needs. These extrusions offer a way to create lightweight, attractive, and functional retail display systems that enhance product visibility and organization in stores.

- We turn quotes around quickly and accurately.

- We tackle unique and challenging designs.

- We quickly adapt and respond to any design changes

- We guarantee on-time delivery given short lead times.

- We offer competitive pricing.

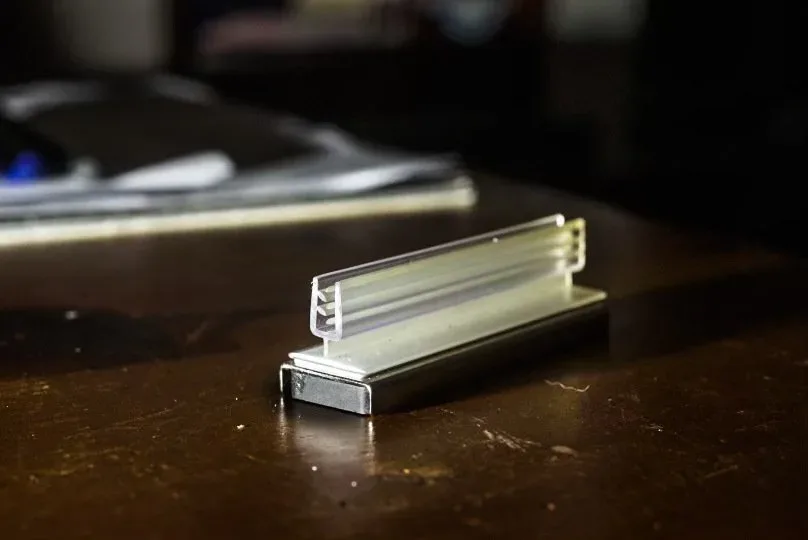

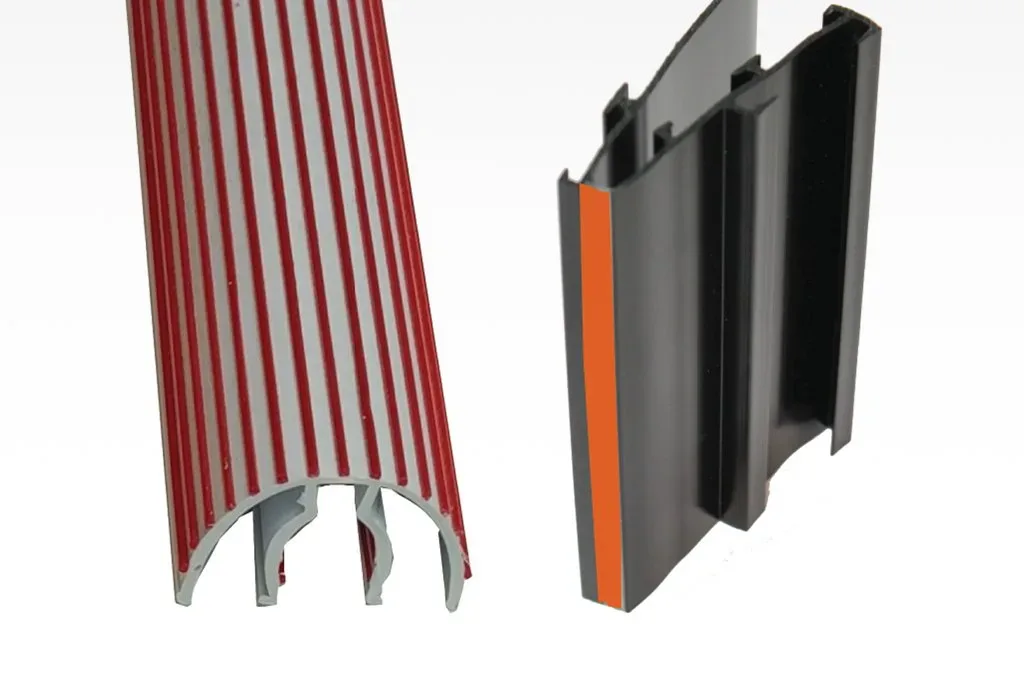

Plastic extrusions are essential in the retail display signage industry for creating sturdy and customizable sign frames, housing illuminated letters, diffusing light, mounting brackets, and protecting signs from damage. In the in-store fixtures industry, they are used to make lightweight shelves, hold and protect price tags, finish and secure display edges, organize products with custom dividers, and enhance lighting for displays. Both industries rely on plastic extrusions to enhance functionality and visual appeal. Jifram leads the industry by providing top-quality plastic extrusions that meet the highest standards.

Sign up For Our Newsletter

"*" indicates required fields

We innovate to produce limitless possibilities

Retail Display plastic extrusions for retail displays manufactured by Jifram can be seen in some of the country’s largest retailers like Target, Home Depot, Lowe’s, Walgreens, and CVS. With more customers starting to shop brick and mortar stores since the pandemic, it’s critical to have retail displays that are high quality and well crafted. Partner with Jifram and find out how our innovation in engineering quality plastic extrusions can give your company a competitive edge.

As your extrusion source, we want to make your job easy.

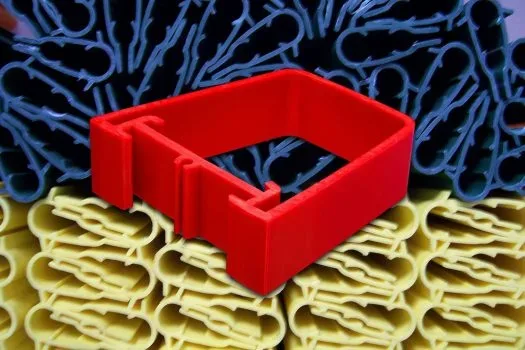

Our plastic profiles will help you supply your customers with these items and more:

- High-Quality Displays, Merchandisers, & Showcases

- Shelf Talkers, Shelf Edging, and Shelf Caps

- Label Holders, Sign Holders, & Graphic Holders

- Edge Trim Bumpers

- Other miscellaneous and custom structural components

Manufacturing versatile plastic profiles is a capability of ours

We can help you find exactly what you need

At Jifram, we also manufacture Co- and Tri-Extrusions so you can customize a variety of finishes, rainbow and metallic-colored profiles, and utilize many materials in a cost-effective solution that meets the needs of your customers.

We will reduce project development costs and improve speed to market with prototype plastic extrusions using advanced SLA technology and 3D printing.

No Minimum Policy

From design concept to full-scale production, Jifram takes care of everything, from small prototype sampling to large volume runs.

There is no plastic extrusion run too short. We’ll bolt that die on the machine and run as little or as many as you need.

For extrusion runs of one or hundreds of thousands, we are your source.

Sizes & Materials

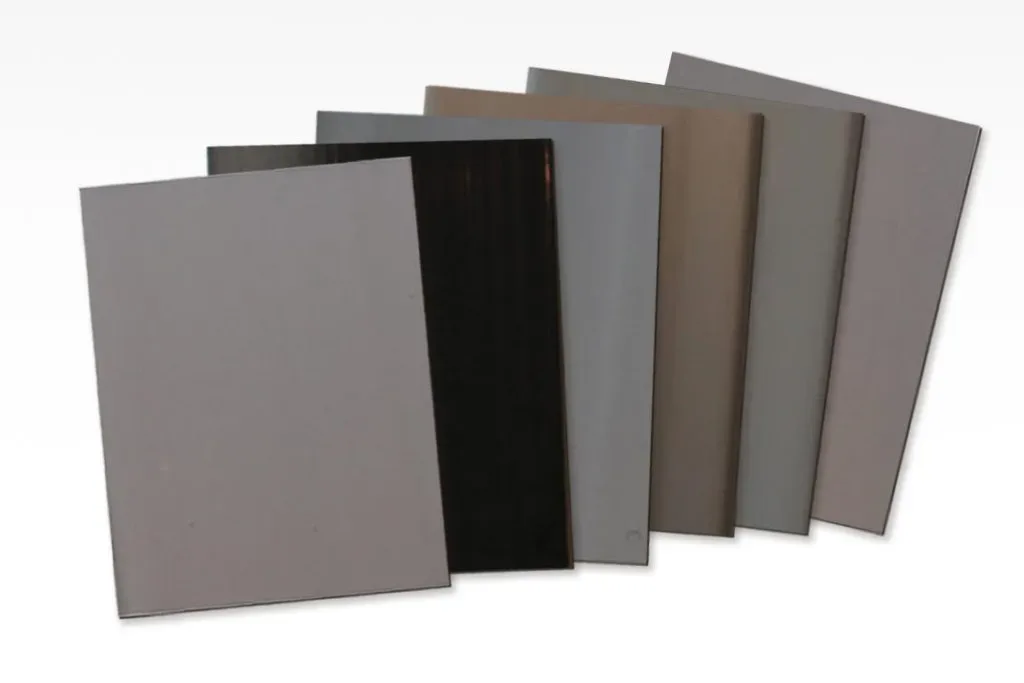

Jifram can manufacture profiles in a variety of colors, materials, shapes and sizes. We offer up to 22 1/2 ” wide, or up to 7″ high, learn more about our Extra Wide and Tall Extrusions ›

Our custom clear plastic acrylic extrusions are durable and chemical resistant, but that’s just one type of material we specialize in.

These are just some of the raw materials we use for our profiles:

- ABS

- Polycarbonate

- Polyethylene

- Polypropylene plastic

- Polystyrene (HIPS)

- Eastman Provista™ Copolymer

- Rigid, Flexible, and Transparent PVC

- Styrolux®

Jifram Delivers So You Can Too

From our website, you can count on instant quotes available 24/7, plus expert assistance in material selection, prototyping, and POP profile design & engineering. We also offer secondary operations, including sawing, embossing, coiling, hot stamping and many more, as well as drop shipping & fulfillment services.

We can help you find exactly what you need

NEED HELP WITH A QUOTE?

CONTACT US WE’LL REACH OUT WITHIN 24 HOURS!

With our engineering capabilities and technical experience, we’re here to collaborate with you to determine the ideal tooling and profiles for your Point of Purchase needs. Let us help! Reach out to us and we’ll respond within 24 hours!