Design Tips

Skillful design ensures:

- Less expensive tooling

- Lower cost per foot

- Reduced time from inception to delivery

- Minimal quality issues during production

Even Wall Thickness

Good Design

Poor Design

Profiles need an even wall thickness throughout.

Large differences can cause unequal material flow through the tool which distorts the profile.

Material will also cool at different rates, causing bowing of the finished extrusion.

Avoid Detail in Hollow Section

Good Design

Poor Design

Hollow extrusions (tubes) are made using a vacuum former.

Internal detail should be kept to a minimum since it is difficult to control during production.

Complex detail can be achieved if the profile is opened up, no longer requiring the vacuum.

Hollows within hollows should be avoided.

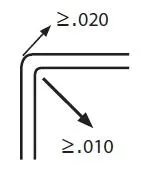

Radius

Good Design

Poor Design

Radii should be as large as possible.

Inside radii should be a minimum of .010” and outside corners should be no less than .020” to eliminate the possibility of notching and cracking in the corners.

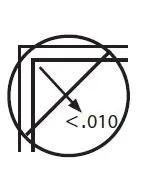

Tolerances

Good Design

Poor Design

Plastic profiles with strict tolerances are difficult to produce because thermoplastics expand and contract at different temperatures.

Greater accuracy is possible if lengths are cut off-line, but it adds cost. A typical length tolerance for extrusions would be +/- 1/16”. Longer lengths would have a greater tolerance.

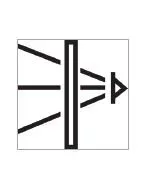

Choosing Clear Materials

Good Design

Poor Design

If clarity is the overriding requirement, wall thickness should be kept to a minimum in any material. There are several plastics that give a clear finish.

Transparent PVC is generally least expensive and suitable for many applications, though not as clear as glass.

Acrylic and PETG (Provista) offer very good clarity; however, profiles need to be relatively simple. Polycarbonate is best for strength and rigidity.

Die lines may be present in clear extruded materials.

Fit and Function – Mating Parts

Good Design

Poor Design

Custom plastic extrusions often need to fit mating parts, such as metal frames, a board or end-caps.

Whenever possible, provide these mating parts to ensure your profile fits and functions properly.