Polycarbonate: A Versatile Solution for Plastic Extrusions

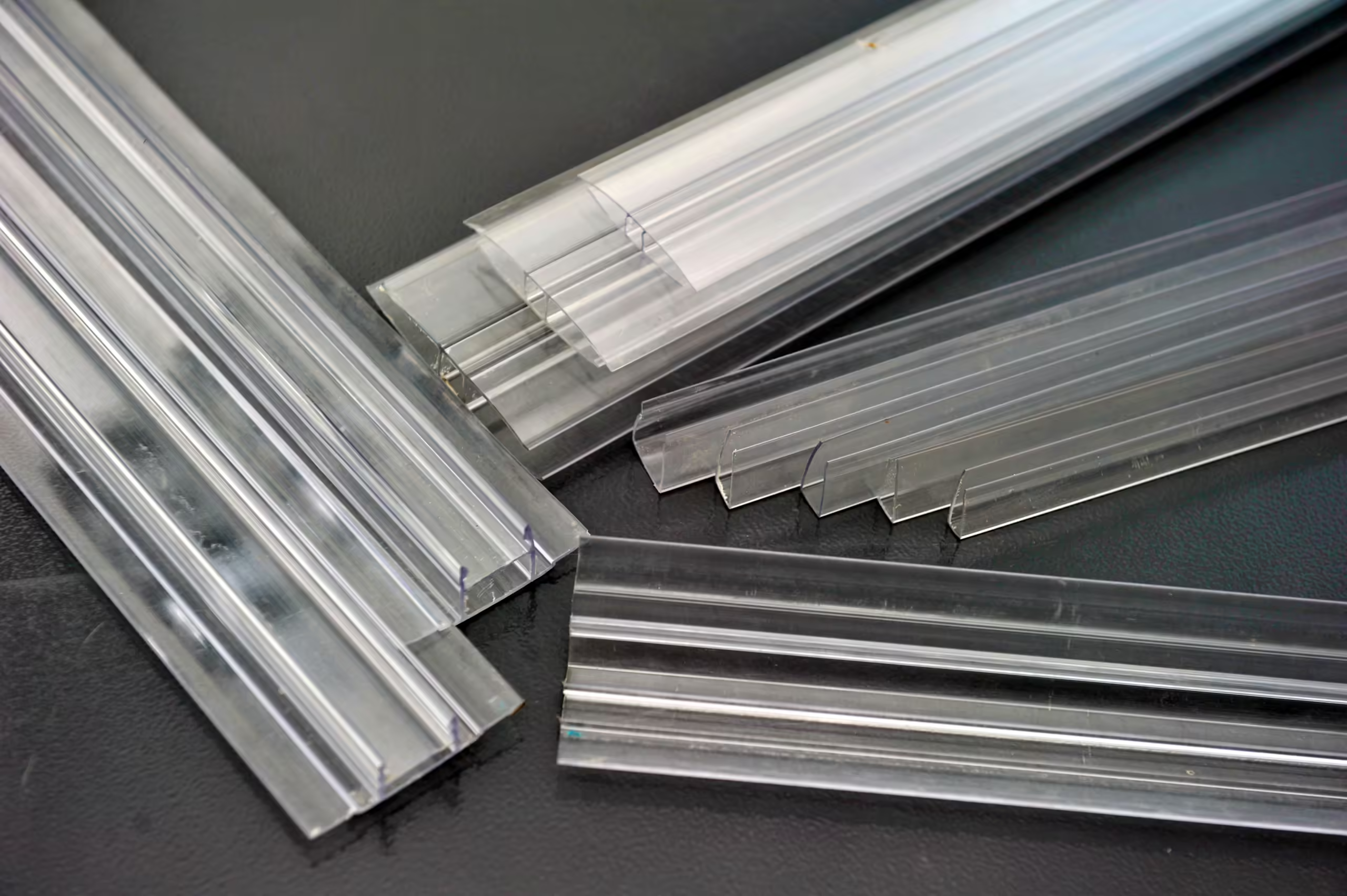

When it comes to durability and versatility in the plastic extrusion industry, polycarbonate stands out as a top contender. Known for its exceptional strength and transparency, polycarbonate is a thermoplastic material that is widely used in various applications ranging from industrial to consumer products. At Jifram, we harness the full potential of polycarbonate to create innovative solutions that meet the demanding needs of our clients.

What is Polycarbonate?

Polycarbonate is a lightweight, impact-resistant plastic that offers high optical clarity. It’s about 200 times stronger than glass and significantly lighter, making it an ideal material for products that require toughness without compromising on weight. This material also boasts excellent thermal stability and electrical insulation properties, making it suitable for both indoor and outdoor use.

Key Applications of Polycarbonate

Polycarbonate is incredibly versatile and finds use in a wide range of industries:

- Safety and Security: Due to its impact resistance, polycarbonate is often used in applications where safety is paramount. This includes protective gear, safety goggles, and even bullet-resistant glass.

- Construction: Polycarbonate is popular in the construction industry for its durability and weather resistance. It’s used in roofing panels, greenhouse coverings, and skylights.

- Lighting: In the lighting industry, polycarbonate is highly valued for its optical clarity and durability. It’s frequently used in lenses and covers for light fixtures, where its ability to diffuse light effectively without compromising strength is crucial. Whether it’s indoor or outdoor lighting, polycarbonate lenses provide the perfect combination of aesthetics and functionality.

- Electronics: The electrical insulating properties of polycarbonate make it ideal for use in electronics, such as housing for electrical components and connectors.

Why Jifram Chooses Polycarbonate

At Jifram, we understand that the material we choose is just as important as the design of the product itself. Polycarbonate’s unique properties allow us to create custom extrusions that deliver both performance and longevity. Whether it’s a specialized part for a complex industrial application or a high-clarity component for a consumer product, our team can design and manufacture polycarbonate extrusions tailored to your specific needs.

Sustainability and Polycarbonate

Polycarbonate is also a sustainable option, as it can be recycled and repurposed, reducing environmental impact. At Jifram, we are committed to sustainable manufacturing practices, ensuring that our use of polycarbonate aligns with our broader environmental goals.

Partner with Jifram for Your Polycarbonate Needs

Choosing the right material is crucial for the success of your project. With decades of experience and a commitment to innovation, Jifram is your trusted partner for high-quality polycarbonate extrusions. Contact us today to learn how we can help bring your next project to life with the durability and versatility of polycarbonate.