The Benefits of Polyurethane in Plastic Extrusion

Polyurethane is a versatile and robust material that has revolutionized the plastic extrusion industry. Its unique properties and wide range of applications make it an essential material for manufacturers looking to produce high-quality, durable products.

What is Polyurethane?

Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. It can be tailored to exhibit a range of characteristics, from flexible foams to rigid plastics, making it incredibly adaptable. This versatility is one of the reasons polyurethane has become a popular choice in the manufacturing world.

Key Benefits of Polyurethane in Plastic Extrusion

Durability and Longevity

Polyurethane is known for its exceptional durability. Products made from polyurethane can withstand harsh environment conditions, making them ideal for outdoor and industrial applications. This material is resistant to abrasion, impact, and wear, ensuring that the extruded products have a long service life.

Flexibility and Versatility

Polyurethane can be formulated to be either flexible or rigid, depending on the requirements of the application. This flexibility allows manufacturers to produce a wide range of products, from soft foams used in cushioning to rigid components used in structural applications. The adaptability of polyurethane makes it suitable for diverse extrusion products.

Chemical and Oil Resistance

One of the standout properties of polyurethane is its resistance to chemicals and oils. This resistance makes it an excellent choice for applications where exposure to harsh chemicals is common. Polyurethane can maintain its integrity and performance even in environments where other materials might degrade.

Load-Bearing Capacity

Polyurethane can bear heavy loads without deforming, making it ideal for applications that require robust support. This property is particularly beneficial in automotive, construction, and industrial sectors, where strength and reliability are paramount.

Cost-Effective

Despite its high performance, polyurethane is a cost-effective material. Its durability and longevity means that products made from polyurethane require less frequent replacement, reducing overall maintenance and replacement costs. Additionally, the versatility of polyurethane allows manufacturers to streamline their production processes, further reducing costs.

Environmental Sustainability

Polyurethane can contribute to sustainability efforts. Many manufacturers are now producing polyurethanes that are recyclable or made from renewable resources. This eco-friendly aspect is becoming increasingly important as industries strive to reduce their environmental impact.

Applications of Polyurethane in Plastic Extrusion

Polyurethane’s unique properties make it suitable for a wide array of applications in plastic extrusion, including:

- Seals and Gaskets: Polyurethane’s flexibility and resistance to chemicals make it perfect for creating durable seals and gaskets.

- Wheels and Tires: The material’s load-bearing capacity and wear resistance are ideal for manufacturing wheels and tires.

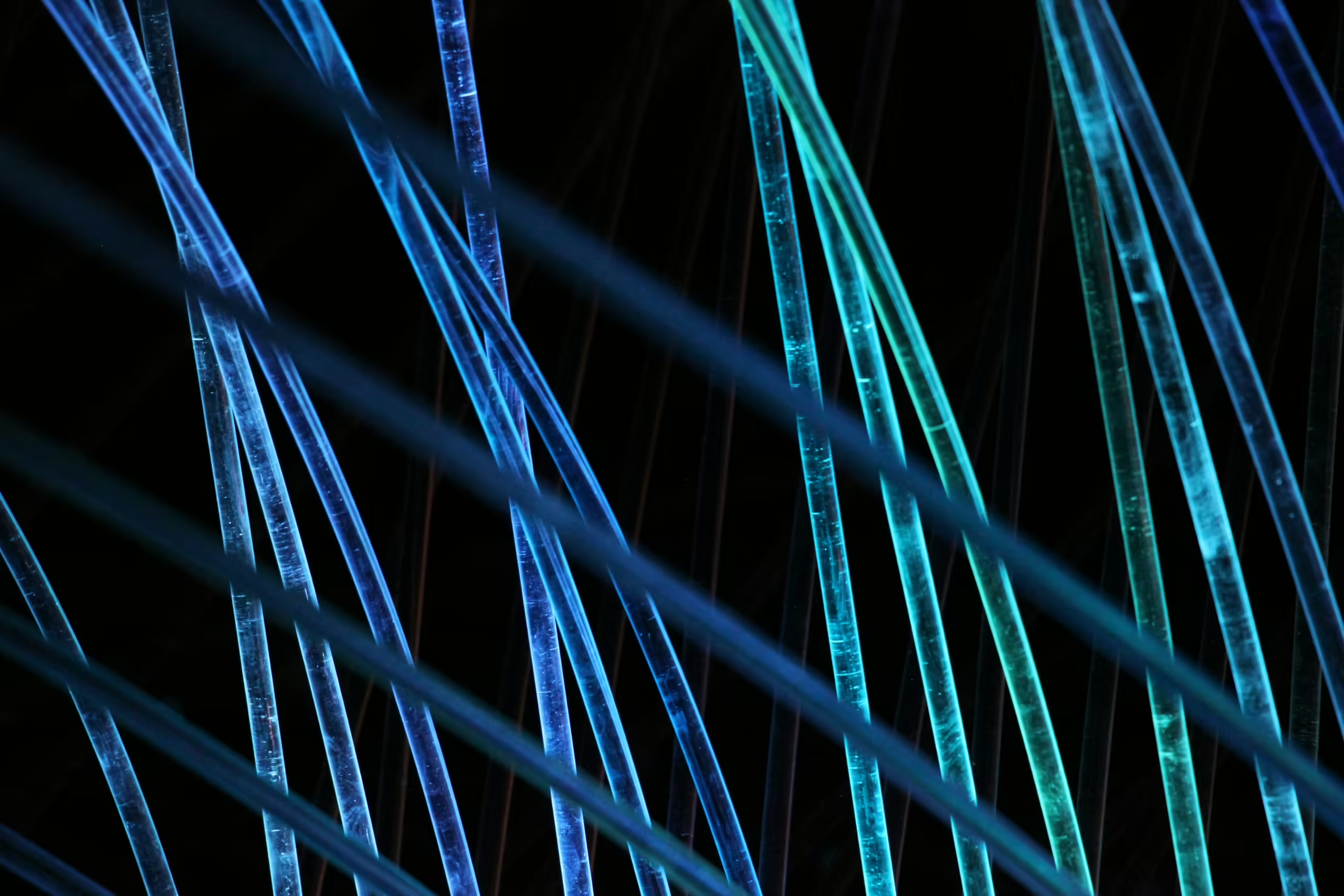

- Hoses and Tubing: Polyurethane’s flexibility and durability make it suitable for hoses and tubing used in various industries.

- Industrial Rollers: The toughness and longevity of polyurethane are beneficial for producing industrial rollers that undergo heavy use.

Polyurethane is a game-changer in the plastic extrusion industry, offering a blend of durability, flexibility, and cost-effectiveness that few other materials can match. Its ability to withstand harsh conditions, bear heavy loads, and resist chemicals makes it an invaluable asset for manufacturers. As the demand for high-quality, long-lasting products continues to grow, polyurethane will undoubtedly remain at the forefront of innovative extrusion solutions.

For more information on Jifram’s custom extrusion solutions, contact us today.