The Versatility of Acrylic in Modern Manufacturing

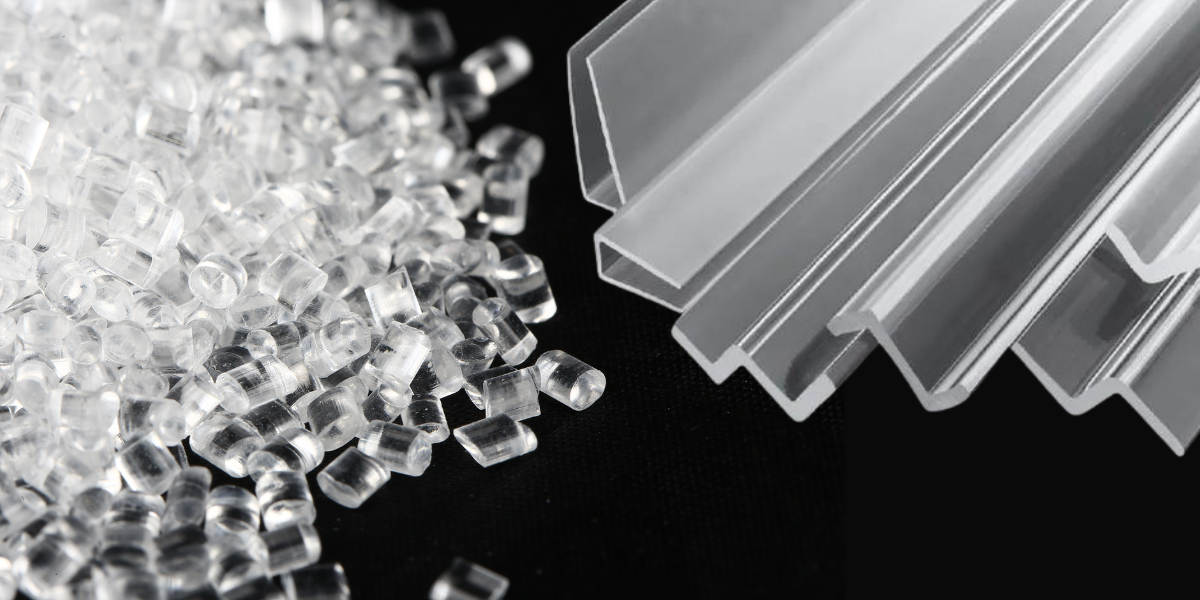

Acrylic, a type of plastic known for its clarity, durability, and versatility, has become a cornerstone material in a wide range of industries. From retail displays to architectural structures, its applications are as diverse as they are innovative. At Jifram Extrusions, we understand the unique properties of acrylic and leverage its potential to create high-quality custom extrusions that meet the specific needs of our clients.

Why Acrylic?

Acrylic, often recognized by its brand name “Plexiglass,” is a popular choice due to its glass-like appearance combined with superior strength and shatter resistance. It is lighter than glass, yet more durable, making it an ideal material for products that require both aesthetic appeal and practicality. Additionally, acrylic is UV-resistant, which means it maintains its clarity and does not yellow over time, even when exposed to direct sunlight.

Applications of Acrylic in Various Industries

Retail Displays: Acrylic’s clarity and strength make it a preferred material for retail displays and signage. Whether it’s for showcasing products or creating eye-catching point-of-purchase displays, acrylic offers the perfect blend of durability and visual appeal. Its ability to be easily molded and fabricated allows for custom designs that stand out in any retail environment.

Medical Equipment: In the medical field, acrylic is often used in the production of protective barriers, medical devices, and laboratory equipment. Its non-toxic properties and ease of sterilization make it a safe and reliable material for critical applications where hygiene and transparency are paramount.

Vehicles Industry: Acrylic is utilized in numerous vehicles for creating light covers, instrument panels, and other components where clear visibility is essential. Its resistance to impact and weather conditions ensures longevity, even under harsh environments.

Architecture and Interior Design: Acrylic sheets are often used in architecture and interior design for features like skylights, partitions, and decorative panels. The material’s ability to transmit and diffuse light makes it a popular choice for creating bright, open spaces. Moreover, its ease of customization allows architects and designers to experiment with shapes, colors, and textures, offering endless possibilities.

Jifram’s Expertise in Acrylic Extrusions

At Jifram, we specialize in transforming acrylic into custom-extruded profiles that cater to the specific requirements of our customers. Our state-of-the-art facility and experienced team ensure that every profile meets the highest standards of quality and precision. Whatever you need acrylic extrusions for, Jifram provides solutions that are both innovative and cost-effective.

Sustainable and Reliable

Beyond its functional benefits, acrylic is also an environmentally conscious choice. It is recyclable, and at Jifram, we are committed to sustainable practices throughout our manufacturing process. By choosing acrylic extrusions from Jifram, you are not only investing in a high-quality product but also contributing to a more sustainable future.

Acrylic’s versatility, durability, and aesthetic appeal make it an invaluable material in modern manufacturing. At Jifram, we harness the potential of acrylic to deliver customized solutions that meet the evolving needs of various industries. Whether you’re looking for retail displays, medical equipment, automotive components, or architectural features, our expertise in acrylic extrusions ensures that your project will stand out with superior quality and design.

For more information on how Jifram can assist with your acrylic extrusion needs, contact us today.